The following instructions apply to the Nettigo Air Monitor in version 0.3.3 STD. If you have a different version, see the Knowledge Base section for instructions. The general principle of soldering and assembly is common to all our sensors - but keep in mind that they differ in details.

I assume the NAM motherboard and HECA are already soldered. So we will not repeat ourselves. You are probably already familiar with the list of the necessary tools, health and safety precautions and soldering methods. If not please take a look at our guide.

¶ Soldering wires

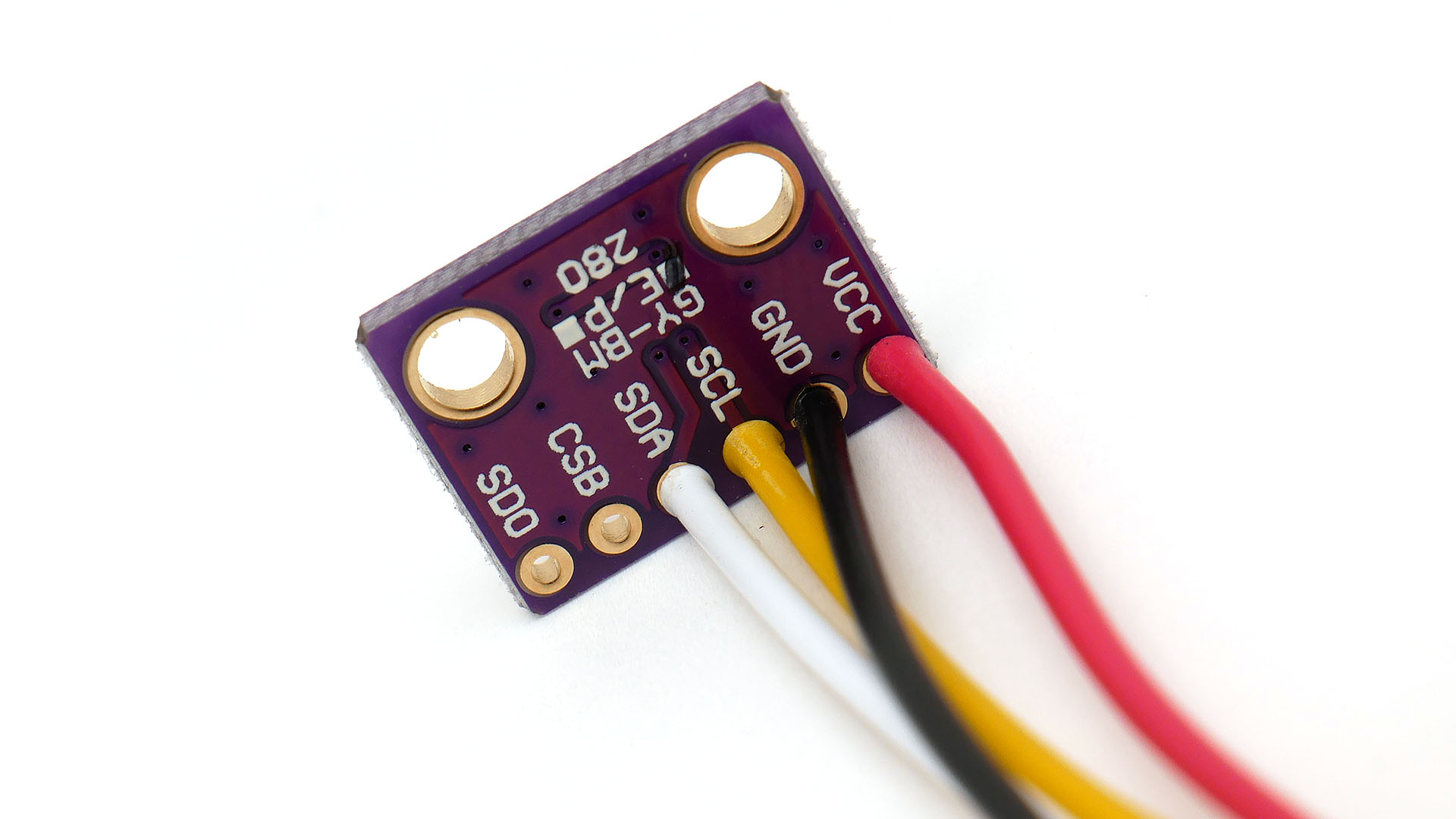

The purple sensor board has 6 solder points. We will only use 4 of them. The cable with 4 color wires and white plug should be soldered as shown in the picture.

- Red - 3V3

- Black - GND

- Yellow - SCL

- White - SDA

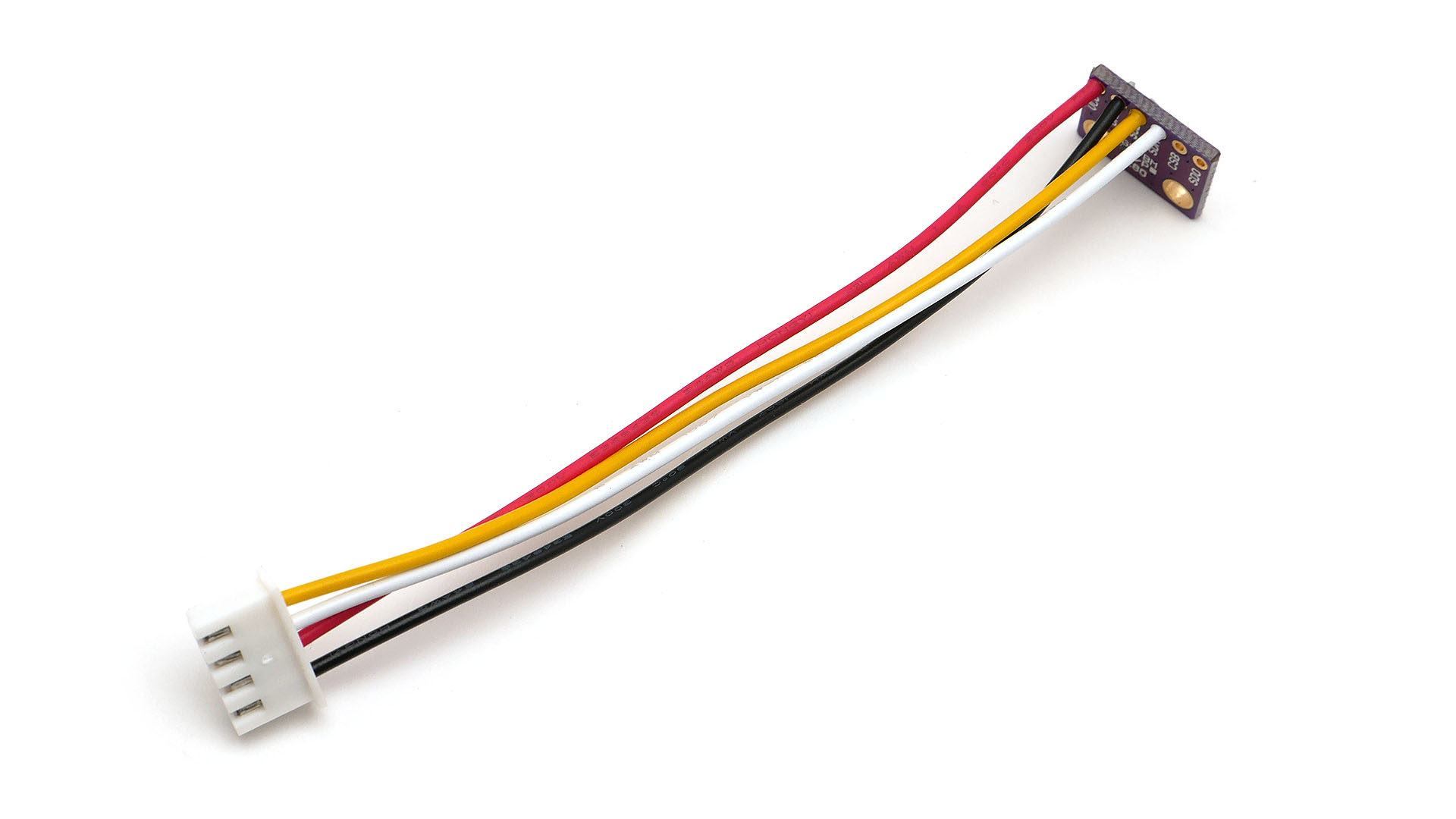

The module with the cable should look like in the picture above. It is a good practice to solder in such a way so the cable insulation touches directly to the module PCB. If cable cores are exposed it's very easy to short circuit them (and that means troubles). Remember that the insulation of the wires shrinks from heat. If necessary, the solder point can be heated again and a single cable can be pushed in a litte more.

¶ Placing in case

Do test Your BME280 module before placing in case!

Before placing BME280 in case test if Your module is working. Use NAM motheboard and connect BME280 to 3.3V I2C socket. Power up NAM (remeber to place board in safe place, where nothing can shortcut joints on lower side of PCB) and log in (I assume You have NAMF already configured when soldering motherboard. If not see config). If there is no reading wait until measurement count will show 1 at least.

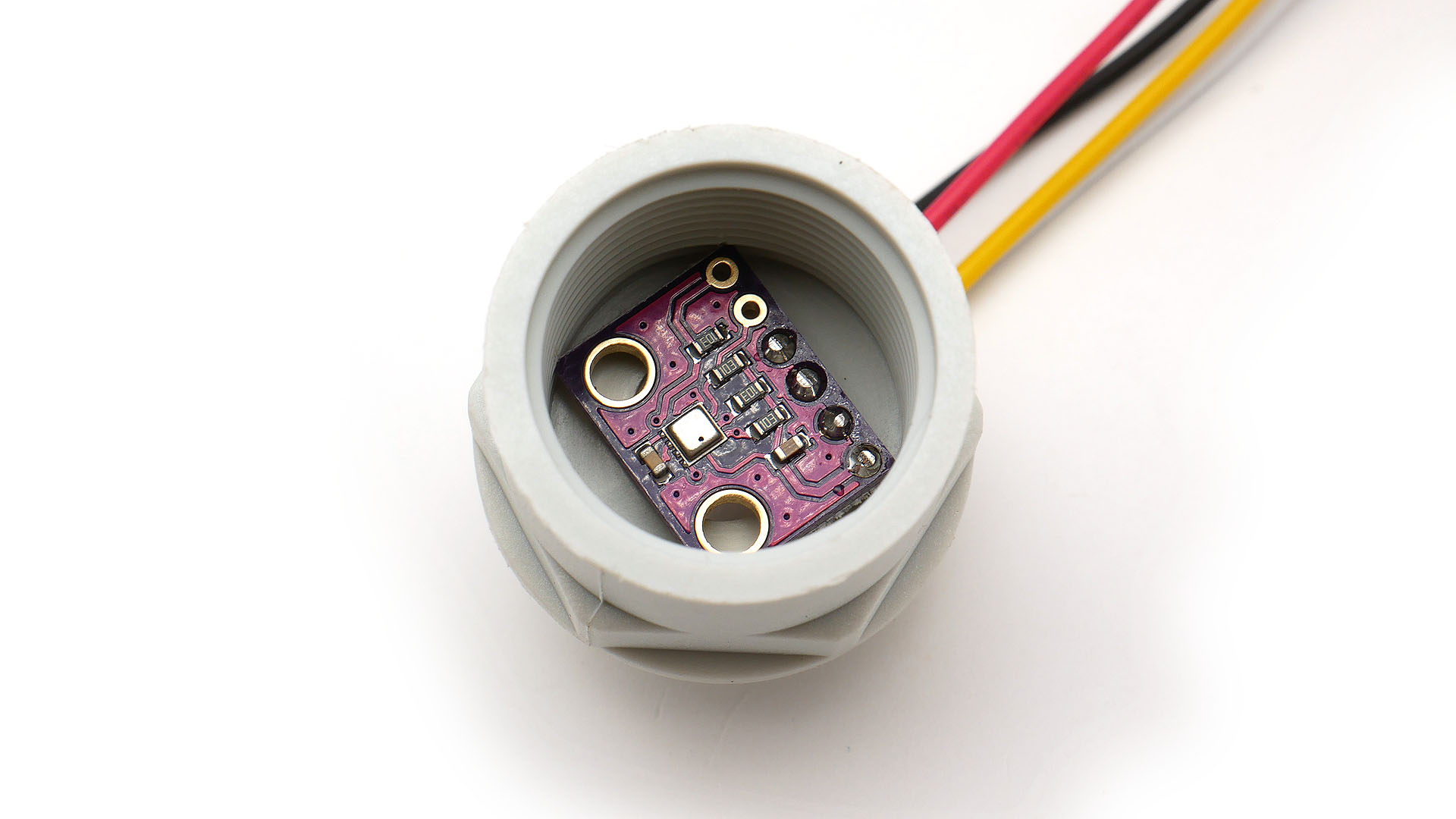

The white XH2.54-4P plug should be put through the opening in the housing. At first glance, it may seem impossible. But the plug goes sideways without any problems.

Place the sensor plate in the center. Don't force it down. If board doesn't fit, you can cut off two corners of the module (those near mounting holes).

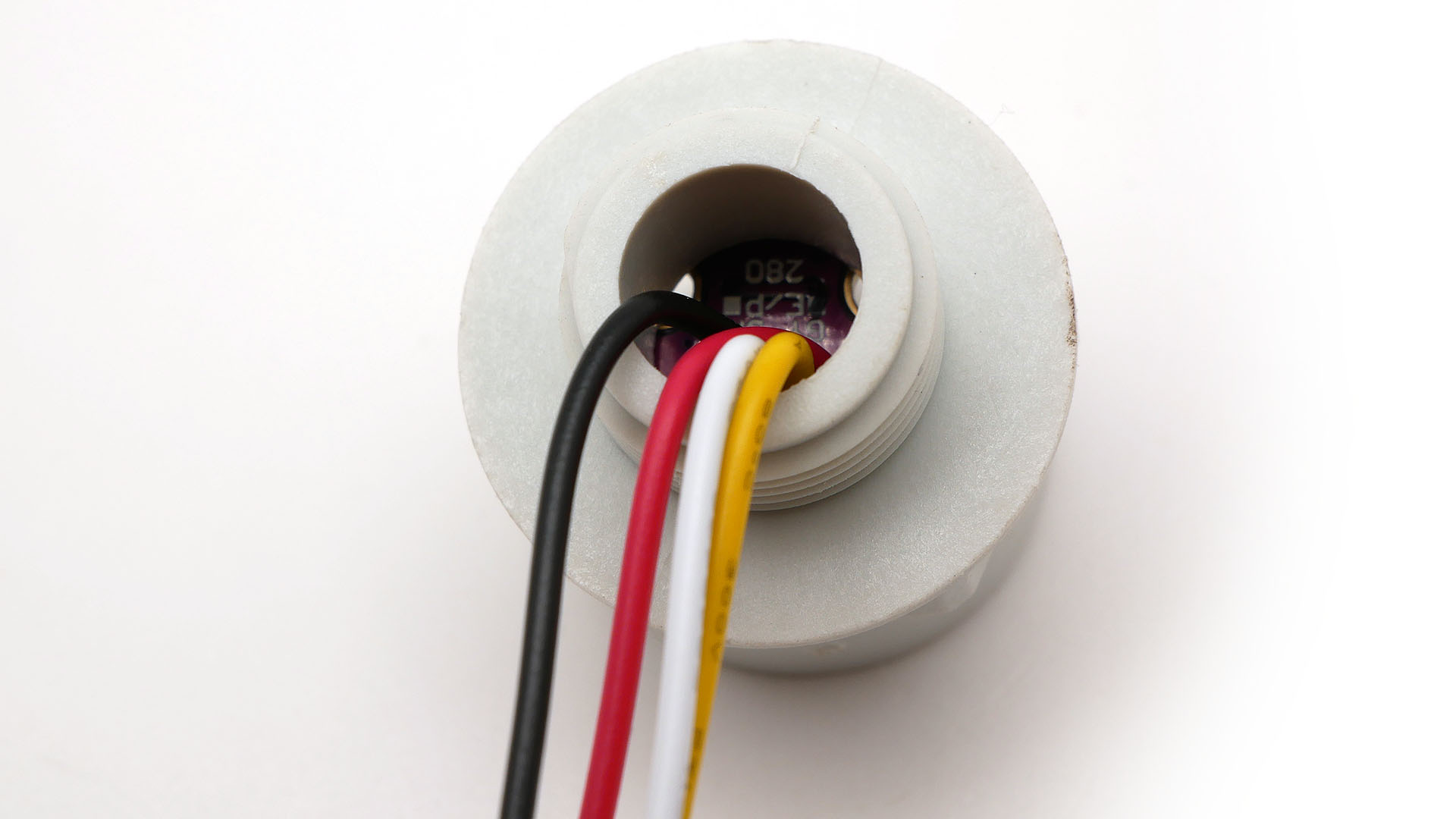

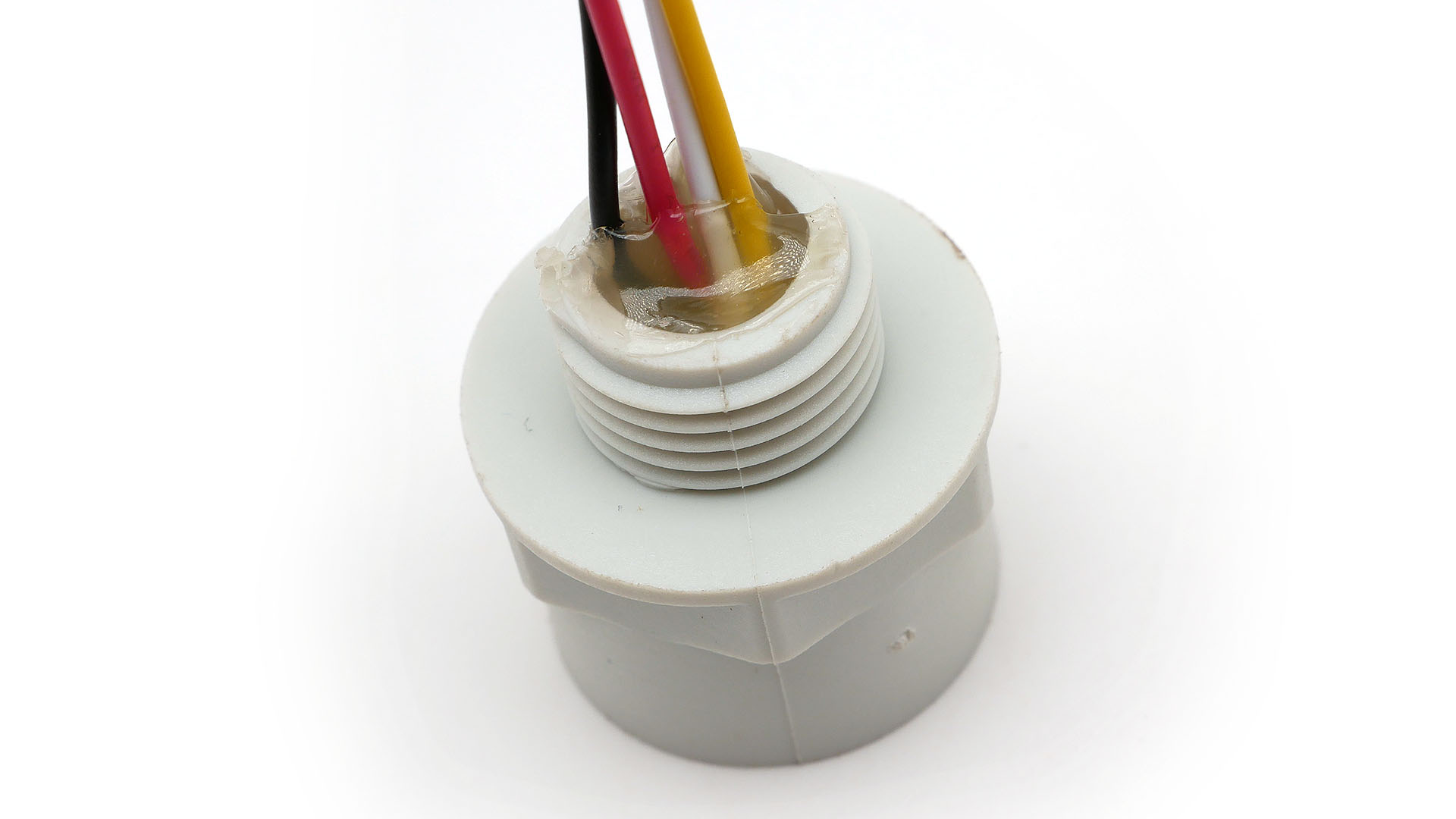

The module is already in the housing, but on the back we have a large hole through which the warm air from the inside of the NAM sensor can heat the BME280 sensor. It is a good idea to fill this gap.

A hot glue is perfect for this. If you don't have hot glue, silicone, or a piece of foam are fine - although for foam we recommend using one that does not absorb water. Electronics and water doesn't mix very well.

¶ Next step

Depending on version of Your kit select next step: